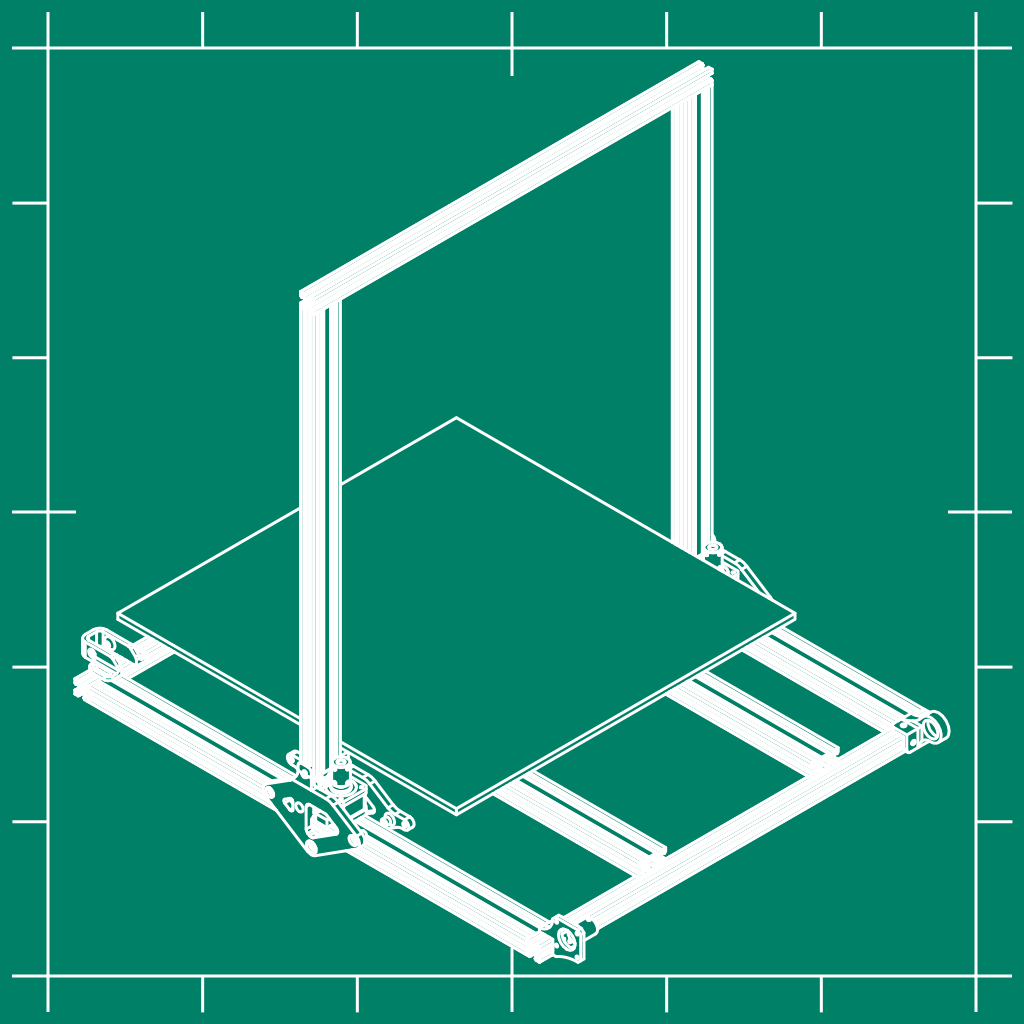

Easy moving portal mod for Creality printers

A simple and reversible moving portal mod which uses mostly reused and 3D printed parts.

Suggested price: €0.00

Additional information

| Version | CR-10, Ender 3 |

|---|

Summary

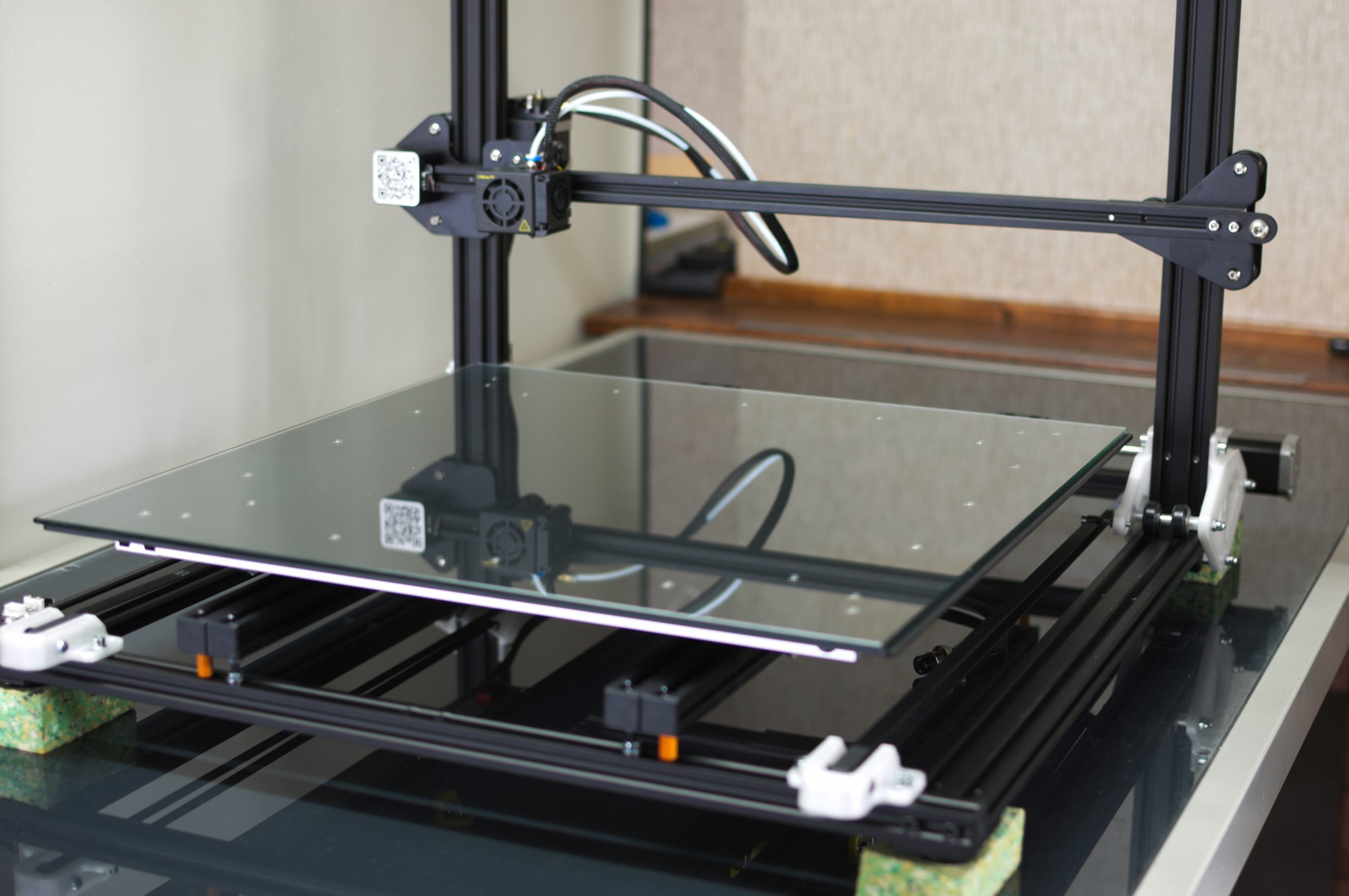

Because I want to print large things out of difficult materials like ABS or Nylon I need an enclosure. I’ve built some enclosures and they are relatively big for its build size due to the Cartesian printer type. Especially with this huge machine I want to reduce its size by making it a moving portal machine. The standard coreXY systems have a cage in which the core is moved in, as the name suggests, the X and Y direction. This is done with a belt driving mechanism and I looked at several options, but I think that my approach would be the simplest. I don’t think it will reach the famous speeds a coreXY printer can reach, but it definitely doesn’t have to move as much weight as a Cartesian style printer has to do.

It uses mostly 3D printed parts and reused parts from the bed so risks and costs are low 🙂

The video I’ve made about this is this one:

I recently did some tests how well it performed and updated the current version because of a design flaw which I show in that video too

Print Settings

Printer: Creality Ender 3 pro and CR-10

Rafts: Yes

Supports: Yes

Resolution: 0.2

Infill: 30%

Filament: Polycarbonate

Notes:

I’ve used polycarbonate because it’s very strong and stiff. This material is definitely not easy to print and other materials like ABS or PETG (maybe PLA even) would work. You probably will not reach the same stiffness, but I recon it would be good enough.

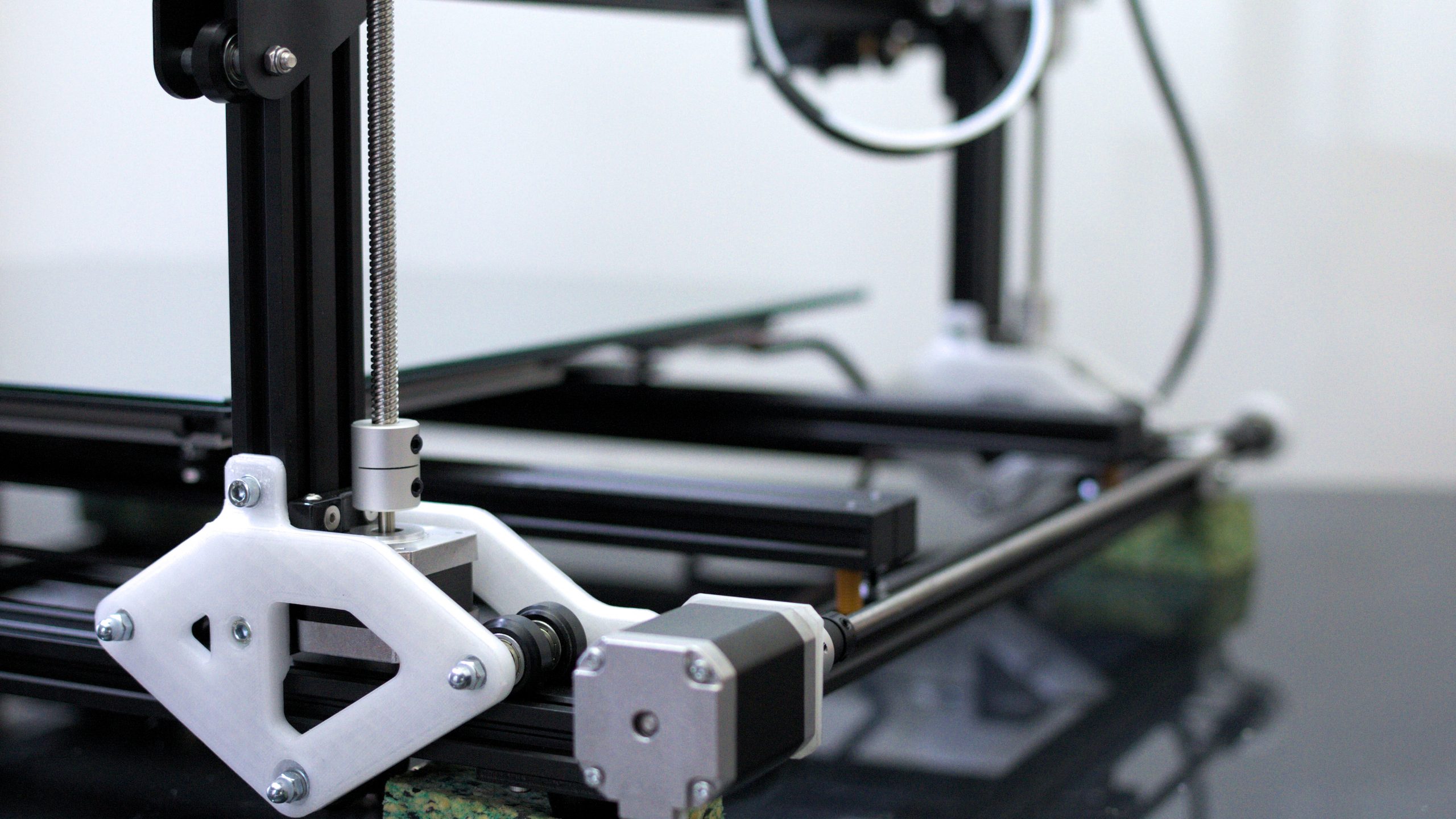

Mounting instructions

The parts you’ll need besides the printed parts and what’s already shipped with the printer:

- 8mm plain unhardened rod.

- Bearing OD22mm ID8mm (608ZZ)

- Motor coupler 8mm to 5mm (similar to Z motor coupler)

- 2× GT2 pulley 20 teeth 9mm belt*, 8mm ID.

- 2× GT2 pulley with bearing 20 teeth 9mm belt*, 5mm ID.

- Extra belt, length varies of the printer type (I had one extra in the value added package of my S5).

- 6× cable tie (4× for mounting the belt and 2× for strain relief of the Z axes).

- M5 threaded rod (cut to length of 6× 70mm) A 70mm bolt would do too.

- 6× or 12× M5 (acorn) nut depending on using a bolt or rod (above point).

- 12× M5 spring washer.

- 23× M5 washer.

- 4× M4×30 bolt for mounting the belt to the base.

- 4× M4 insert (use nuts on each side of the bolt if you don’t have inserts or tap M5 thread in it and use M5)

- 4× M4 nut to secure it.

- 2× M5×35 for the belt tensioners.

- 2× M5 lock nut for the belt tensioners.

- 2× M5×20 flat head bolts and replace the bolts at the back which stick out a bit colliding with the motor and bearing bracket.

- 22× M5×10 bolts

- 22× M5 t-slot nuts

- 6× M5×20 bolts for mounting the bed (or shorten or just use the ones already used for the bed)

- 8× M5×45 or longer for the new bed leveling system

- 16× M5 nut

Looking at it, this looks like a long list, but it’s mostly standard nuts and bolts. Please let me know of you have questions or if I have forgotten something! The YouTube video shows briefly how this thing is put together and it should be pretty straight forward.

The only way to connect everything without cable extensions is by placing the control box at the back of the printer as I show in the video. I am going to make a whole enclosure so the wiring as I’m going to do it would be completely different. Keep in mind that you have to find a way to get this working for your specific situation!

You must be logged in to post a review.

Reviews

There are no reviews yet.