The story behind the TIME-system

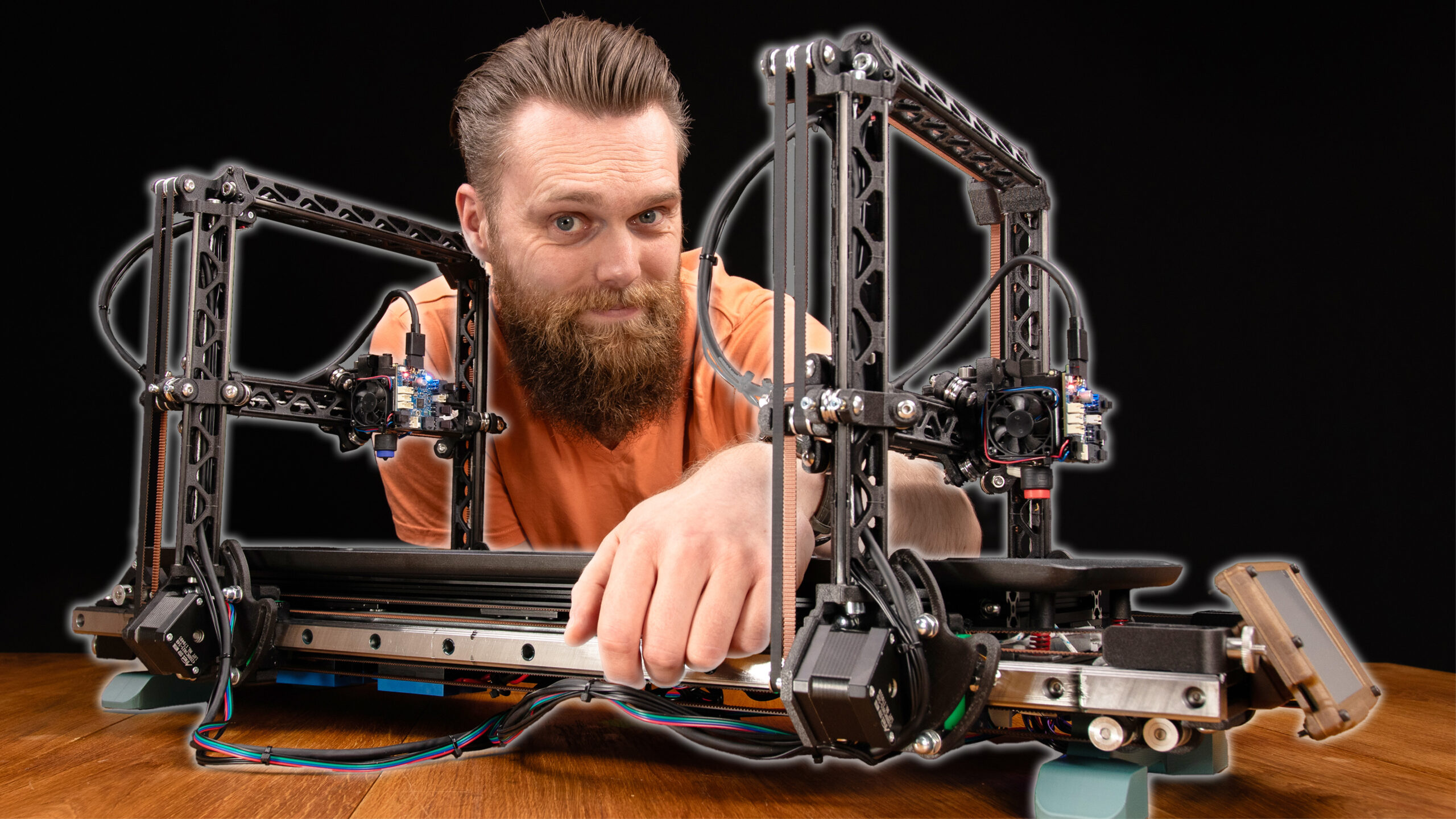

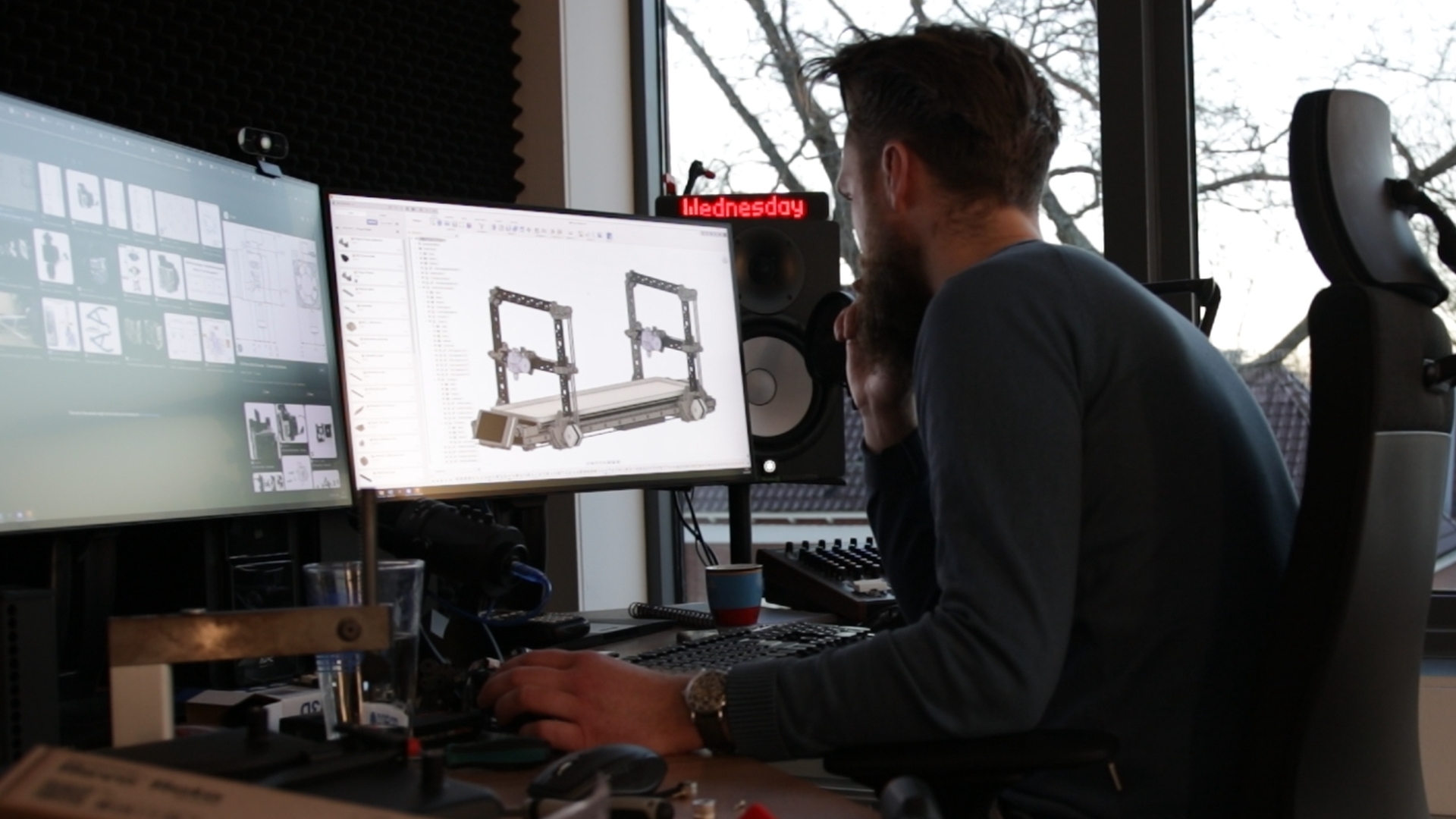

Over the last couple of months, I developed a 3D printer with a motion system that I call the TIME-system. This stands for True Independent Multiple Extrusion, but more on that later. I shared that recently in this YouTube video and it gained quite a lot of attraction. Yet, the comments showed that the intentions of this could benefit from some clarification. In this article you’ll read the why, how and what of this system.

First, let’s start with why. Why would I go through the trouble of all of this and why should you follow the progress? Why on earth did I combine two printers on one platform and didn’t use a regular tool change system?

OK, I firmly believe in its potential, which I will talk more about further down in this article. Yet, the main reason for me to even start something like this, is that I believe in the importance of trying things out, even if it doesn’t look like the best option out there. I believe that this is where innovation could arise. This is the message I want to convey. If the voice in your head says something like: “wouldn’t it be cool if…” Yes, do it.

Yet, with this system I had a hunch that it might actually enable possibilities that aren’t possible with the obtainable 3D printers out there. With obtainable, I mean a 3D printer that I actually can get my hands on to try out the things that I want. Now that I developed my own 3D printer, I have the possibility to modify it to my liking and have full control over it. This will be our experimental platform!

So, what is this potential that we’re talking about? To be honest, I don’t know its full potential and that’s what I like about this project. That’s also what I like about sharing this on YouTube because together we can find its full potential. I read every comment and I will try out the most interesting ones. Maybe someone in the world who watched that video gets inspired by it and comes up with something new. This thought alone keeps me going.

I also thought about several use cases myself that we are going to explore.

Combining materials

I start with what I think is the biggest one; combining totally different materials. I don’t mean like PLA and TPU that can be done on a printer like the Prusa XL. I’m talking about printing glue in each subsequent layer, so a sandwich of a regular polymer like PLA and glue. This is cursed, I know, but would this improve layer adhesion? I already developed a non-pulsating peristaltic pump that I can just slap on there and call it a day. At least, this is what I keep telling myself.

Or what about printing concrete infill to make parts heavier or modify its center of gravity? Maybe just filling the part with concrete can make the part stiffer. Or, maybe we can dissolve a polymer like ABS and start printing with ABS slurry and dump that in the print! Oh wait, and this one: what if the extruder that I developed can place fiber (continuous fiber printing), infuse that with UV resin, let that cure mid-air and print a lattice structure using non-planar 3D printing. Another reason why the core-XZ system makes so much sense!

To sum it up: we are going to combine polymers, pastes/liquids and fibers/wires in one single part, slap it under a car and drive off into the sunset. A man can dream right?

Printing like a belt-printer

A belt printer uses a conveyor belt as a build plate. The gantry is tilted at a 45-degree angle and in this configuration it’s possible to print very long parts. Obviously, with the printer I’m building we still have the restriction of the bed’s length. So, what is the advantage here?

3D printed shoes. This is the first thing that I want to print on this printer. We won’t utilize the two tools in this case, but we will try other things. In the 45-degree configuration it prints from front to back. During the print it’s possible to adjust the print temperature. There is a material called Varioshore that will foam depending on this print temperature. The hotter it’s printed, the more it foams, the softer it gets. We can use this to make custom insoles. The shape of the shoe itself is also very suitable to be printed in this configuration, also for the aesthetics!

I’m working together with several companies on this behind the scenes and things will become clear later on in upcoming videos! These shoes will be epic.

Printing in parallel

To be honest, I don’t see big advantages here, if any. Two regular 3D printers next to each other will achieve the same thing. Yet, I see this as an interesting challenge to see if I can modify G-code in such a way that this becomes possible. This being said, I cannot exclude the option that we will find an interesting use case for this. We will definitely learn new things or come up with new ideas, just by trying this out. This is my motto and I stand by it.