Solving Creality K1 Under-Extrusion While Also Boosting Performance

The Creality K1 is a well-regarded 3D printer, because it provides very fast printing speeds at a reasonable price. But Jón’s K1 experienced a common issue: under-extrusion. In his most recent video, Jón solved that problem and gave the Creality K1 a significant performance boost along the way.

Creality K1 Under-Extrusion

Early versions of the Creality K1 were prone to under-extrusion, which means that the extruder cannot physically push enough filament through the hot end to keep up with the print. Creality fixed that problem on newer models and even offered an affordable extruder replacement for owners of the early models. But Jón wasn’t able to snag one when they were available, so his K1 sat as a glorified paperweight.

When consistent under-extrusion like this occurs, it is sometimes possible to “fix” the problem by slowing print speeds down until the extruder can keep up. But that didn’t work in Jón’s case. Even at slow speeds, his K1 exhibited significant under-extrusion and that made the printer unusable. Many other K1 owners have this same problem.

And, of course, the whole point of the K1 and its CoreXY kinematic system is to print at blazing-fast speeds. Slowing down would be like driving a Ferrari in first gear all the time because of a bad transmission.

The Fix

Jón’s solution is pretty straightforward: swap out the original extruder for a better one. But because this is Jón we’re talking about, you know he wasn’t lazy about it. His fix works with a variety of different extruders, so you can likely use an extruder you already have in your parts bin.

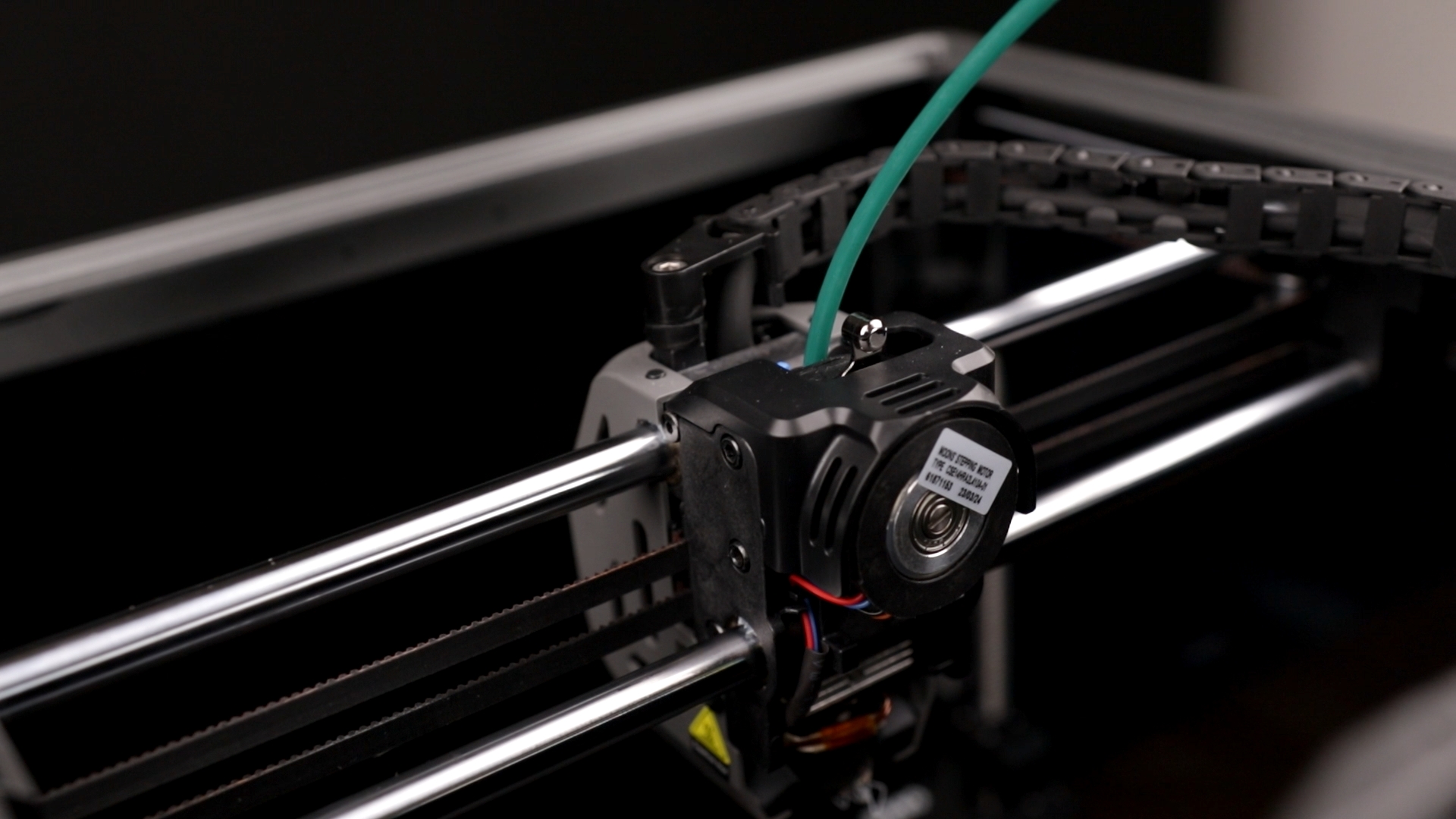

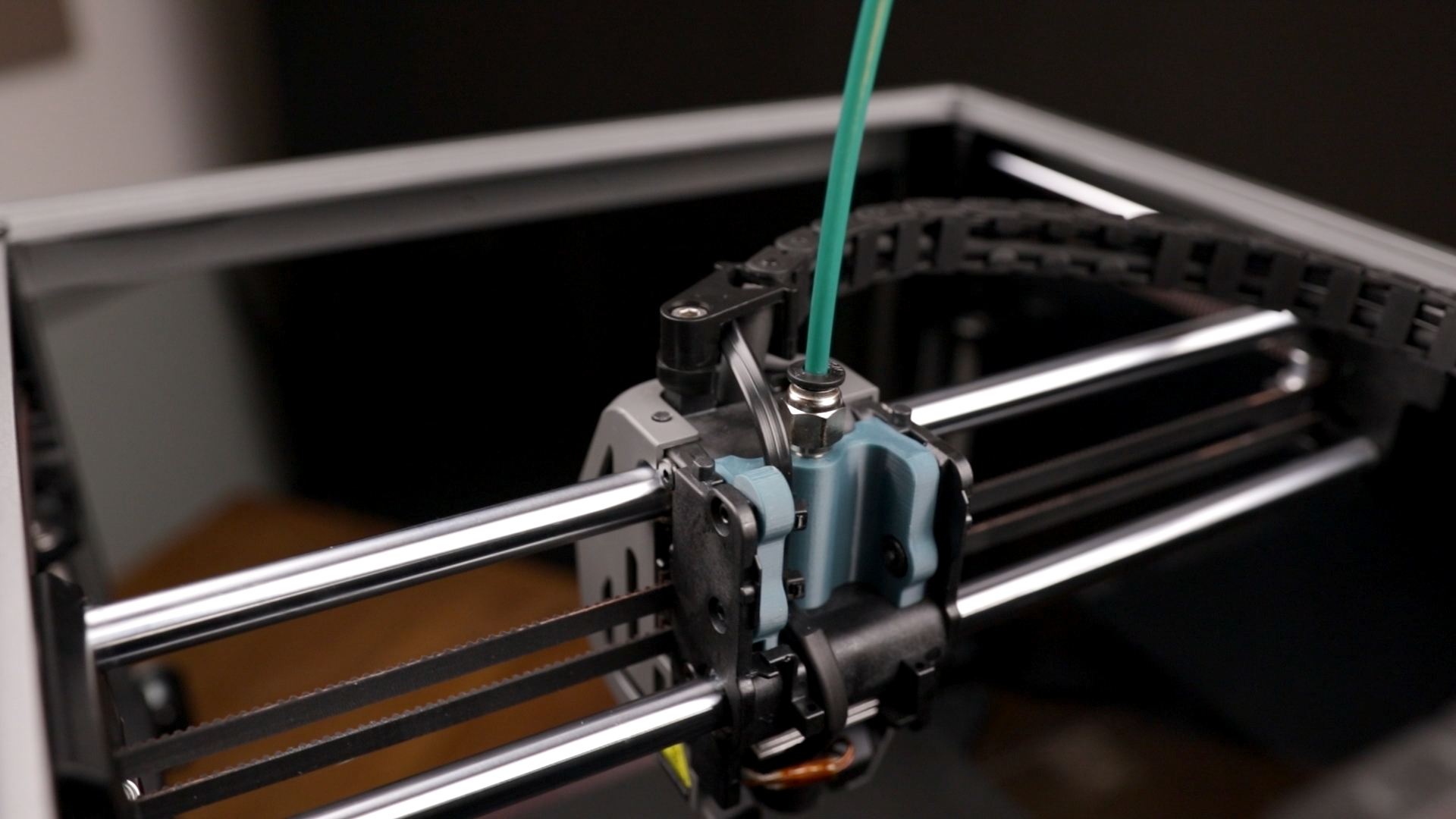

Jón chose a Bondtech QR-right-hand model (affiliate link), which is very powerful. That can act as a direct-drive or Bowden extruder. The K1’s stock extruder is a direct-drive, but Jón chose to use the Bondtech QR as a Bowden extruder in order to achieve the best speeds possible.

Many factors influence an FFF (Fused-Filament Fabrication) 3D printer’s speed, but moving mass is arguably the most important after overall frame rigidity. Because inertia is a thing, the mass of the extruder has a direct correlation with acceleration. The better the acceleration, the sooner a printer can reach its top speed. A Bowden setup relocates the mass of the extruder and extruder motor to a fixed position, dramatically reducing the moving mass and increasing speed.

The Bondtech QR is much heavier than the Creality K1’s stock extruder and a Bowden setup was necessary just to avoid an increase to the moving mass. In fact, it went in the other direction and the extruder moving mass dropped from 155g to 15g—a reduction of about 90%. The reduced moving mass lets Jón’s modified K1 print even faster than an equivalent model with Creality’s official extruder fix.

Increased printing speed is always nice, but the real draw here is the elimination of the K1’s under-extrusion problem. A much more powerful stepper motor and a beefier extruder design ensure consistent and reliable extrusion, even at high speeds.

Performing the Mod

As usual, Jón uploaded the CAD files, BoM, and instructions for this project to this site. Anyone with a Creality K1 can grab those and achieve the same result. Jón designed this so that it doesn’t require any permanent modification of the printer and is fully reversible. The extruder mount is also universal and will work with many different extruder models.

Using a few 3D-printed parts, off-the-shelf fasteners, a Bowden tube and couplers, and a Molex PicoBlade connector set, Jón converted the K1 to a Bowden extruder setup. The new extruder mounts onto the back of the K1 and feeds filament through a Bowden tube to the stock hot end on the extruder carriage. By taking advantage of the existing extruder motor connector and mounting holes, these parts attach without any irreversible modifications to the K1.

If you perform this mod and later decide that you don’t like it, you can easily return the K1 to its original condition.

Testing

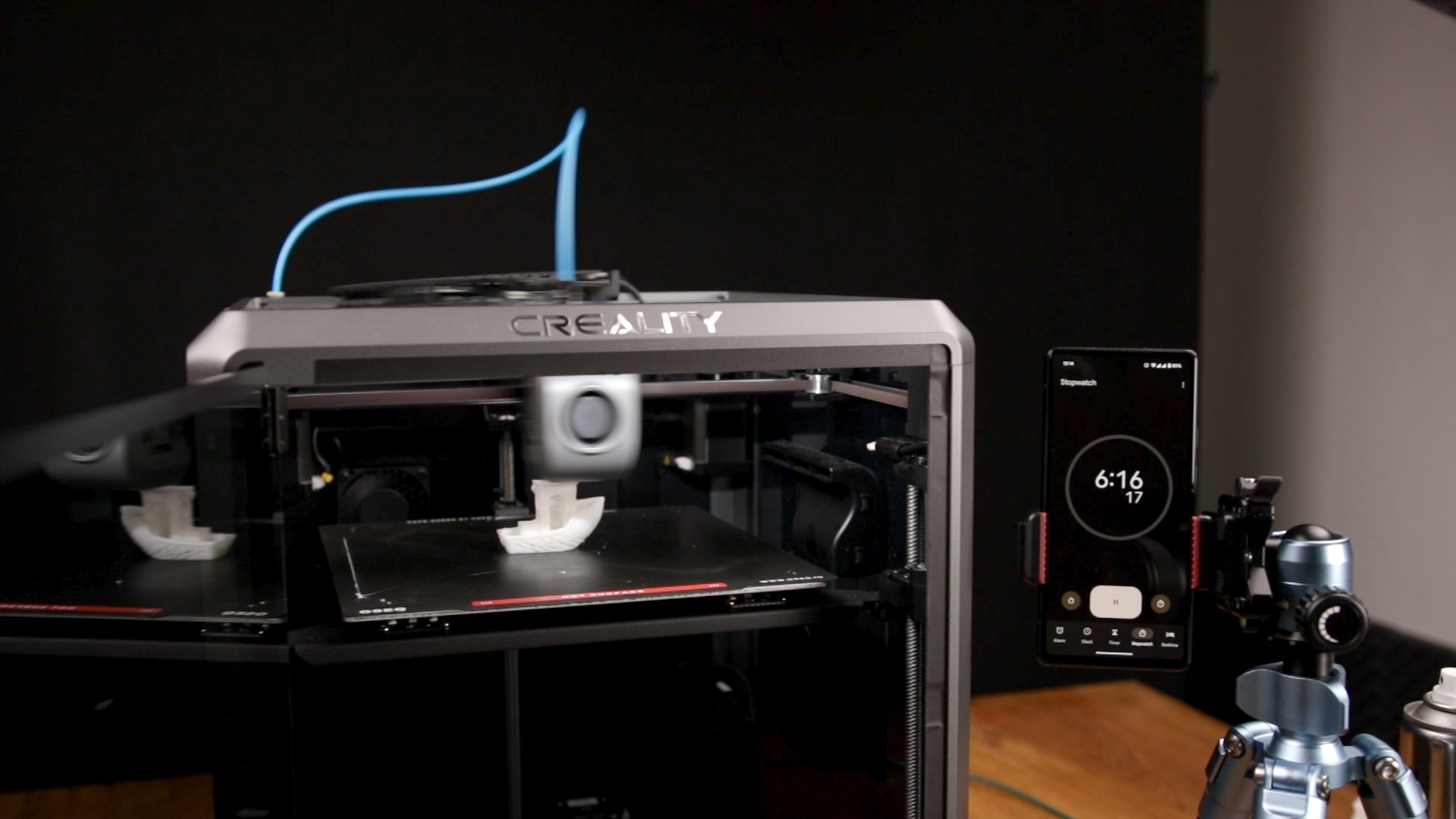

There were a couple of early mishaps caused by a lackluster Bowden tube and an underperforming nozzle. Jón fixed those by switching to a nice Capricorn PTFE Bowden tube and a high-flow Bondtech CHT nozzle.

Right off the bat, Jón could see that the under-extrusion issue was gone. But he wanted to push the K1 to its new limit and so, naturally, he printed a speed Benchy.

That completed in just 6 minutes and 50 seconds, which is pretty incredible. Not only did Jón solve the K1’s under-extrusion issue, but he also gave it a solid speed boost.

If you own a Creality K1 that under-extrudes, this is the solution you’ve been looking for. As a nice bonus, it should let you print even faster.

And if you haven’t already, be sure to subscribe to the Proper Printing YouTube channel. Jón just celebrated the exciting 100,000 subscriber milestone, so you can expect plenty of awesome content going forward.